|

| August 14, 2012 | Volume 08 Issue 30 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Parker takes liquid cooling to the next level

Parker Hannifin unveiled a game-changing new thermal-management system for cooling critical power conversion, motor, and battery storage systems in hybrid motors for heavy equipment (both vehicle and land-based building types) earlier this year. Precision Cooling Systems, a business unit of Parker, has adapted its long-established, patented evaporative cooling technology into a system that uses a non-corrosive, non-conductive fluid to vaporize and efficiently cool hot surfaces on contact.

The flexibility of Parker's technology has made it easy to implement in many industrial applications ranging from power electronics (IGBTs) in industrial motor drives to grid-scale lithium-ion batteries for big-time energy storage. The coolant is electrically non-conductive, making it a safer alternative to water for high-voltage applications like power electronics, lithium-ion batteries, and ultra-capacitors.

The refrigerant-based, two-phase cooling system also provides over two times the thermal performance, with only 25% of the flow rate required by water cooling. This allows for smaller pumps and fluid lines, which results in less power required to cool the equivalent system whether a battery, motor, power module, or combination of all three. These compact, high-performance systems leverage Parker's long-established portfolio of thermal solutions and technology, and offer a cost-effective alternative for applications in hybrid heavy-duty equipment.

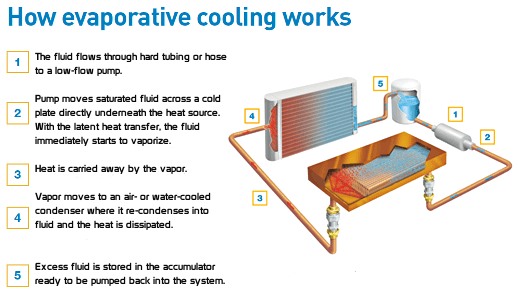

How it works

Parker's two-phase evaporative cooling system uses a refrigerant that is non-corrosive and non-conductive to cool electronics in a closed-loop, highly efficient system that is fully modular, as well as lighter, safer, and more reliable than traditional thermal systems. The system uses a small pump to deliver just enough coolant to the evaporator - usually a series of one or more cold plates optimized to acquire the heat from the device being cooled. The two-phase coolant vaporizes to maintain a cool, uniform temperature on the surface of the device. Then, the vaporized coolant is pumped to a heat exchanger, where it rejects heat to the ambient, and condenses back into a liquid, completing the cycle. The benefits are palpable:

- Smaller, lighter, safer, and more reliable than traditional cooling systems;

- To to four times better heat transfer;

- Evaporative cooling system is isothermal, meaning it dynamically optimizes to heat load;

- 40% increase in electronics throughput;

- Enables up to 2X the power density in the same space;

- Uses 80% less liquid, which means less weight and less space;

- 85% reduced energy consumption for cooling;

- Modular and scalable;

- No altitude or hot-climate de-rating necessary; and

- Maintenance free.

Industrial applications/markets served

Parker's evaporative precision cooled system is currently being deployed in and targeted to a variety of industrial markets, including renewable energy (solar inverters and wind turbine converters), hybrid-electric heavy-equipment motor-drive and storage systems, and large factory-scale medium-voltage motor drive applications.

Precision Cooling Systems is part of Parker's portfolio of thermal management technologies and systems for key industrial applications. For more information, please visit Parker Precision Cooling Systems at www.parkerprecisioncooling.com.

Also see a more extensive PDF here.

Source: Parker Hannifin - Precision Cooling Systems

Published August 2012

Rate this article

View our terms of use and privacy policy